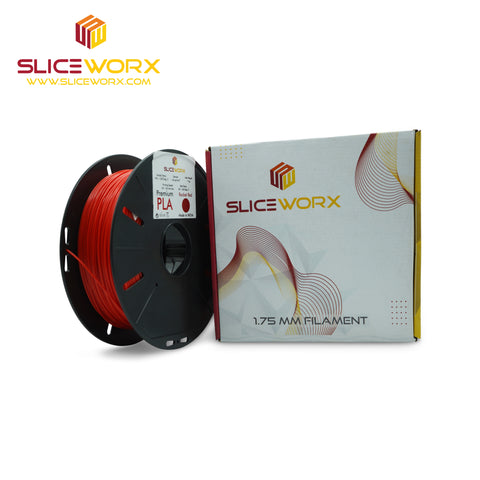

SLICEWORX Flexible Series 1.75mm Filament - Red 95A TPU Filament for 3D Printers

SLICEWORX Flexible Series 1.75mm Filament - Red 95A TPU Filament for 3D Printers

Flexible Filament Qualities:

Flexible TPU Filament: We wanted to create a flexible filament that was easy to print on regular printers and yet had superior printability on high speed corexy printers. Our TPU filament can be printed easily with superior control and layer adhesion for your most complex prints. Print bike grips, flexible bracelets, toy and diy robot parts and living hinge style parts using our TPU filament.

HIGH ACCURACY WITH ±0.03MM DIAMETRIC TOLERANCE: We are obsessed about printing consistency. Due to this reason, we have accurately processed filament with advanced quad sensor-based diameter measuring and self-adaptive control systems in the manufacturing process to ensure strict conformity to tolerances. You will notice a substantial improvement in print quality when using our filaments versus other commercially available filament.

CONSISTENT SMALL BATCH MANUFACTURING: Our filament is made in-house at our factory in small batches to keep the quality parameters in control and ensure color consistency. Our colors will remain the same whether you purchase them this year or the next year!

We perform strict quality control on the molten plastic through multi filtration process and diameter conformity testing using ovality and diametric sensors.

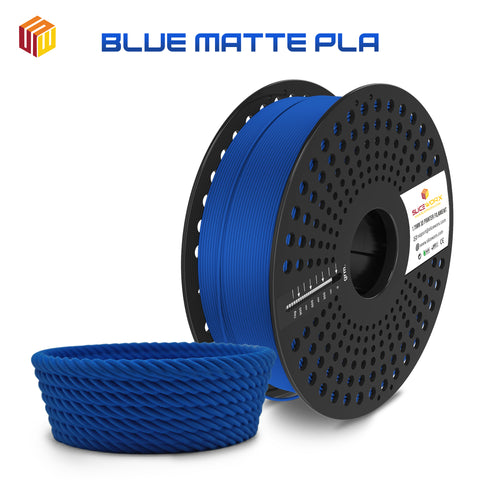

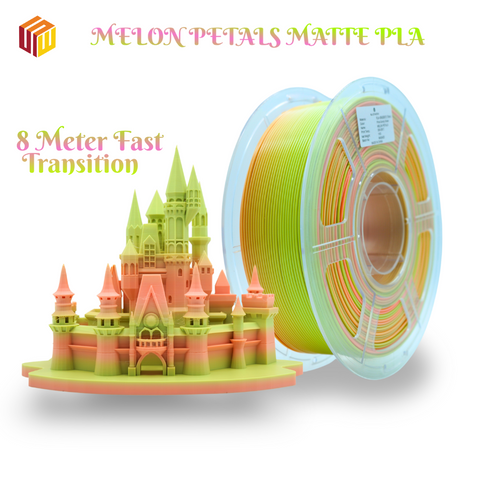

SUPER BRIGHT COLORS: We have created RAL Code based masterbatches with high quality formulations to provide bright colors post printing. The printed parts will have a less reflective finish on the surface with zero glossy white sheen in visible spectrum of light.

TPU PRINTING PARAMETERS: For SliceWorx PLA Filament the recommended extrusion/nozzle temperature is 210°C - 230°C and bed temperature of 50°C - 70°C. to work in perfect harmony with all common 1.75mm FDM 3D printers.

MOISTURE FREE AND BUBBLE FREE: We use a dehydration process and vacuum-sealed packaging bags for enclosing filament to guarantee a consistent and repeatable FDM 3D printing experience. Each box of filament comes with a free zip n lock polythene bag for storing the filament once printing is paused.

UNIFORM WINDING: Fully mechanical servo based uniform winding to ensure that the filament ends are arranged neatly and there is no internal looping. Grooves to hook filament ends on the edge of our spools and end locking of filament ensures no self-unspooling occurs when printers perform retractions even when very less filament remains on the spool.

GUARANTEE AND SERVICE: We provide a 30-day Money-back if you're not fully satisfied or if there is a defect in our products. We provide email and chat online support on all our products.

If you have any questions or concerns about our filament, you can contact us via our email support@sliceworx.com with your order number in subject line.

SPECIFICATION

- Material: 95A TPU - Vacuumed Sealed with desiccant

- Shore Hardness: 95A

- Weight: 1Kg Spool- 1000 gram net weight of TPU material

- Diameter: 1.75mm (+/- 0.03mm)

- Recommended extruder temperature:210 - 230°C

- Recommended platform temperature: 50 - 70°C

Important Notes:

- Initial Dehydration is not required for this material on opening the package. However TPU is very hygroscopic. We recommend drying in a filament dryer at 45C for 2 hours once it has been left open on the printer for more than one day at over 30% room humidity.

- We recommend using Direct Drive extruder for printing TPU. Bowden extruder can be used but do note that bowden tubes do not provide good control of retraction and this may lead to excessive stringing. You will have to print with retraction completely disabled at extremely slow speeds.

- For Bambulab users- You can use this TPU in Bambulab printers using the Generic TPU default settings with absolutely no changes.

SLICEWORX

3D Printer Accessories

26 In Stock

SLICEWORX Flexible Series 1.75mm Filament - Red 95A TPU Filament for 3D Printers

Flexible Filament Qualities:

Flexible TPU Filament: We wanted to create a flexible filament that was easy to print on regular printers and yet had superior printability on high speed corexy printers. Our TPU filament can be printed easily with superior control and layer adhesion for your most complex prints. Print bike grips, flexible bracelets, toy and diy robot parts and living hinge style parts using our TPU filament.

HIGH ACCURACY WITH ±0.03MM DIAMETRIC TOLERANCE: We are obsessed about printing consistency. Due to this reason, we have accurately processed filament with advanced quad sensor-based diameter measuring and self-adaptive control systems in the manufacturing process to ensure strict conformity to tolerances. You will notice a substantial improvement in print quality when using our filaments versus other commercially available filament.

CONSISTENT SMALL BATCH MANUFACTURING: Our filament is made in-house at our factory in small batches to keep the quality parameters in control and ensure color consistency. Our colors will remain the same whether you purchase them this year or the next year!

We perform strict quality control on the molten plastic through multi filtration process and diameter conformity testing using ovality and diametric sensors.

SUPER BRIGHT COLORS: We have created RAL Code based masterbatches with high quality formulations to provide bright colors post printing. The printed parts will have a less reflective finish on the surface with zero glossy white sheen in visible spectrum of light.

TPU PRINTING PARAMETERS: For SliceWorx PLA Filament the recommended extrusion/nozzle temperature is 210°C - 230°C and bed temperature of 50°C - 70°C. to work in perfect harmony with all common 1.75mm FDM 3D printers.

MOISTURE FREE AND BUBBLE FREE: We use a dehydration process and vacuum-sealed packaging bags for enclosing filament to guarantee a consistent and repeatable FDM 3D printing experience. Each box of filament comes with a free zip n lock polythene bag for storing the filament once printing is paused.

UNIFORM WINDING: Fully mechanical servo based uniform winding to ensure that the filament ends are arranged neatly and there is no internal looping. Grooves to hook filament ends on the edge of our spools and end locking of filament ensures no self-unspooling occurs when printers perform retractions even when very less filament remains on the spool.

GUARANTEE AND SERVICE: We provide a 30-day Money-back if you're not fully satisfied or if there is a defect in our products. We provide email and chat online support on all our products.

If you have any questions or concerns about our filament, you can contact us via our email support@sliceworx.com with your order number in subject line.

SPECIFICATION

- Material: 95A TPU - Vacuumed Sealed with desiccant

- Shore Hardness: 95A

- Weight: 1Kg Spool- 1000 gram net weight of TPU material

- Diameter: 1.75mm (+/- 0.03mm)

- Recommended extruder temperature:210 - 230°C

- Recommended platform temperature: 50 - 70°C

Important Notes:

- Initial Dehydration is not required for this material on opening the package. However TPU is very hygroscopic. We recommend drying in a filament dryer at 45C for 2 hours once it has been left open on the printer for more than one day at over 30% room humidity.

- We recommend using Direct Drive extruder for printing TPU. Bowden extruder can be used but do note that bowden tubes do not provide good control of retraction and this may lead to excessive stringing. You will have to print with retraction completely disabled at extremely slow speeds.

- For Bambulab users- You can use this TPU in Bambulab printers using the Generic TPU default settings with absolutely no changes.