Sliceworx Creality K1 Max Flex Dipped Plate Textured Spring Steel Sheet 310x315mm for K1 MAX

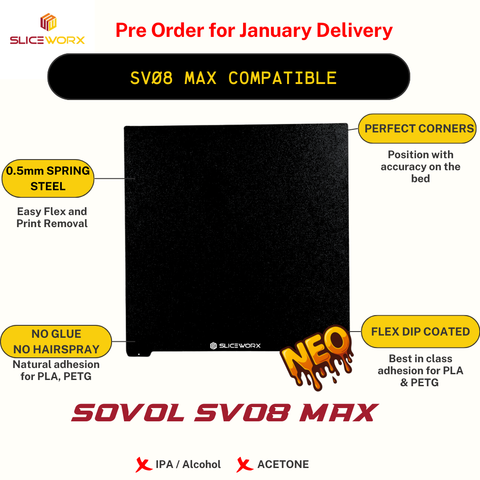

Creality K1 Max Compatible Flex Dipped PEI -Style Textured Spring Steel Sheet 310x315mm for K1 MAX 3D Printer

-

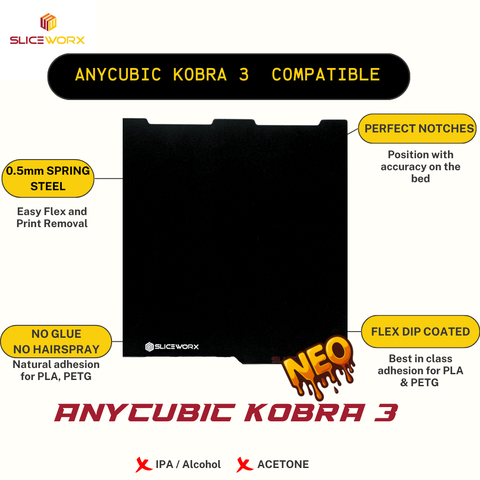

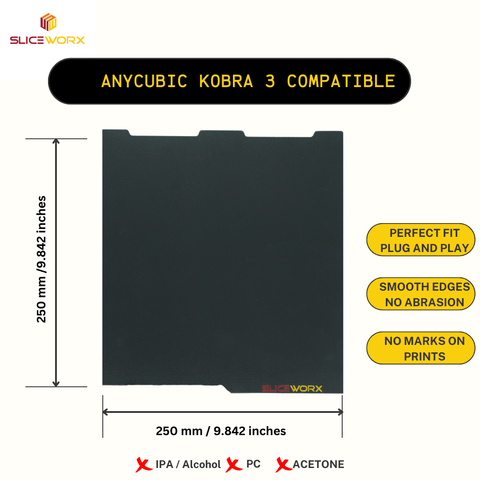

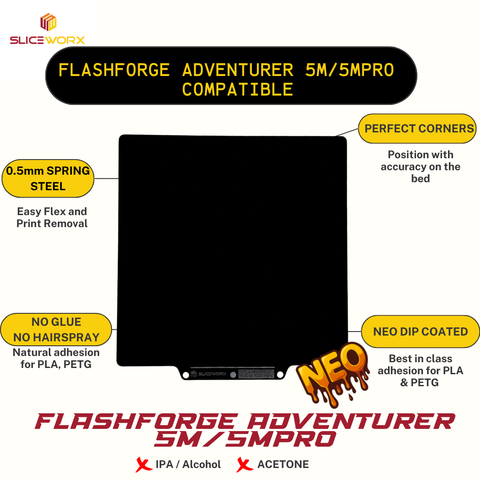

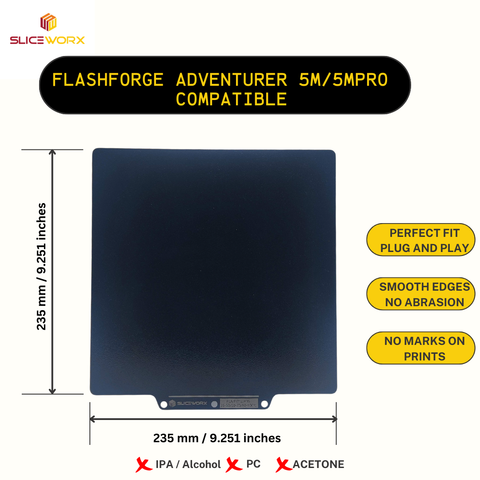

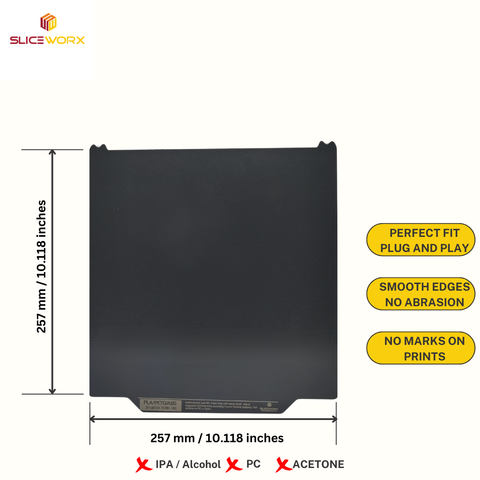

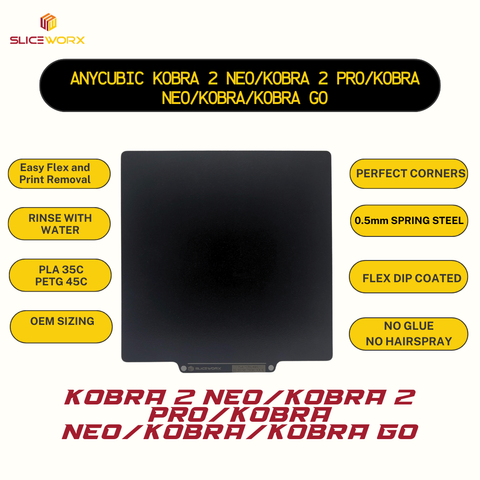

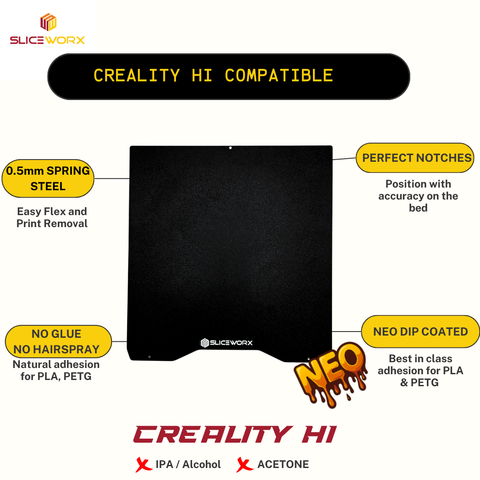

Versatile: Product is compatible with Creality K1 Max and similar bed size printers.

-

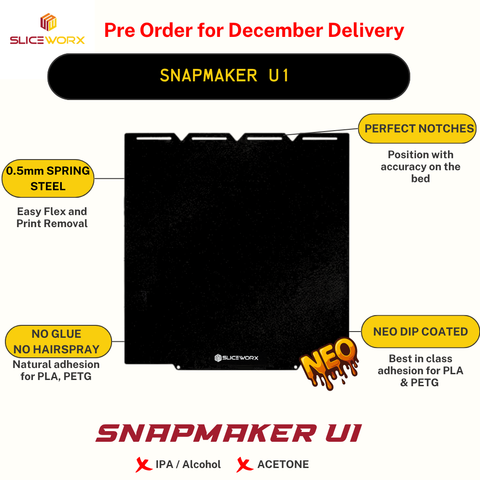

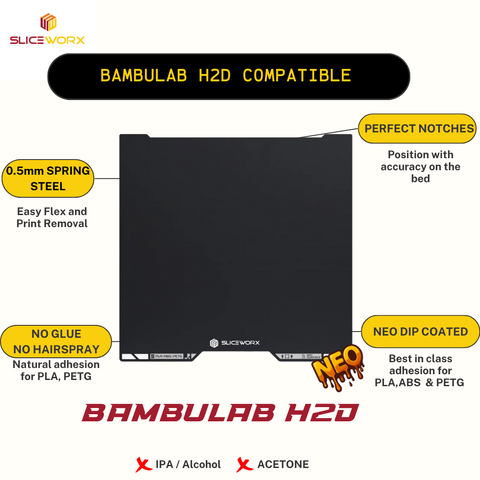

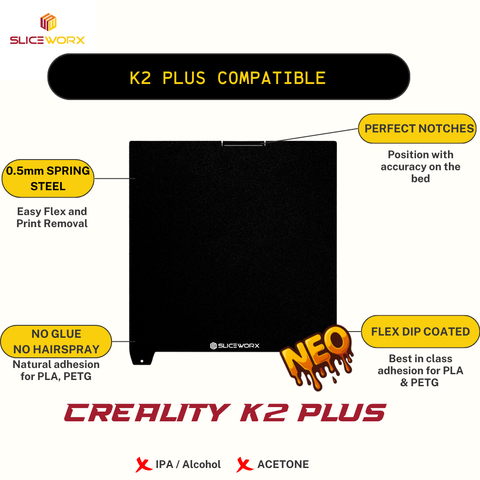

Material : Spring stainless steel with 0.125mm coating PEI powder sprayed then dipped in high quality polymer based coating for power adhesion to the surface.

- Properties: Flexible, removable, and holds to the magnetic sticker very well. High strength and heat resistance.

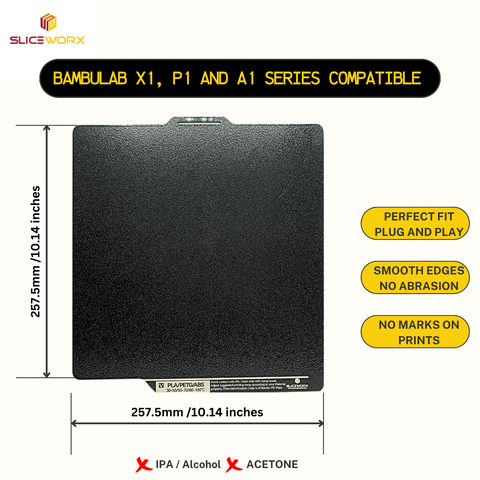

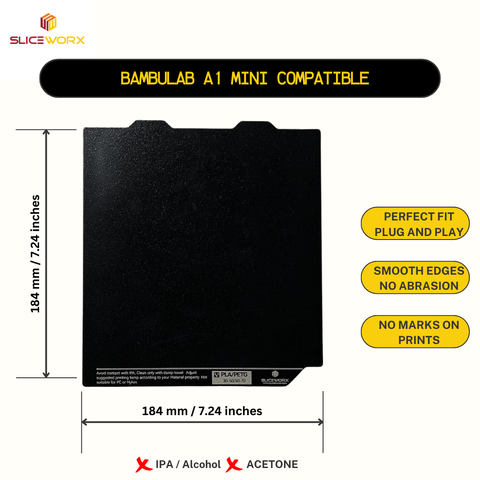

- Quality: The flexible surface can easily be applied to all Bambulab beds making it perfect for plug and play printing.

- Use: Your prints in PLA, ABS and PETG adhere to the printing surface readily, easy to remove the prints, flex slightly to pop your print right off. We strongly recommend you DO NOT print using TPU, ASA,STTPU,PLA FLEX, TPU Derivative, Polymaker Polysmooth PLA/PVB, PC or NYLON on this surface.

- High Temp compatible: Since we have used high quality spring steel of 0.5mm it can withstand thousands of heat cycles that a 3D print bed goes through from print to print without losing coating properties.

- Compatible Printers : All Creality printers where the Heated Bed plate measures 310mm x 315mm are compatible. Compatible with PLA/PETG/ABS only.

**Not Compatible with TPU,ASA,STTPU,PLA FLEX, Polysmooth PLA/PVB, Nylon and PC filament. PC or PCCF will permanently bond to the surface.

Notes :

- Use only water to clean the build surface. No detergent or solvents are needed. Strictly do not use IPA, Alcohol or Acetone to clean the surface. This will destroy the coating and properties and the plate may be rendered unusable.

- Do not print TPU, ASA, Nylon, PC or PC CF or any PC blend filament on the surface. Nylon and PC will permanently fuse with the build surface rendering it useless for any further prints.

- For prying skirts,brims and other thin parts on the build surface use a plastic build plate scraper only. Using a steel spatula or metal blade may permanently scratch and damage the build plate.

- Keep the build plate clean with a damp cloth to prevent grease build up from touching and handling the plate during part removal.

SLICEWORX

3D Printer Accessories

35 In Stock

Creality K1 Max Compatible Flex Dipped PEI -Style Textured Spring Steel Sheet 310x315mm for K1 MAX 3D Printer

-

Versatile: Product is compatible with Creality K1 Max and similar bed size printers.

-

Material : Spring stainless steel with 0.125mm coating PEI powder sprayed then dipped in high quality polymer based coating for power adhesion to the surface.

- Properties: Flexible, removable, and holds to the magnetic sticker very well. High strength and heat resistance.

- Quality: The flexible surface can easily be applied to all Bambulab beds making it perfect for plug and play printing.

- Use: Your prints in PLA, ABS and PETG adhere to the printing surface readily, easy to remove the prints, flex slightly to pop your print right off. We strongly recommend you DO NOT print using TPU, ASA,STTPU,PLA FLEX, TPU Derivative, Polymaker Polysmooth PLA/PVB, PC or NYLON on this surface.

- High Temp compatible: Since we have used high quality spring steel of 0.5mm it can withstand thousands of heat cycles that a 3D print bed goes through from print to print without losing coating properties.

- Compatible Printers : All Creality printers where the Heated Bed plate measures 310mm x 315mm are compatible. Compatible with PLA/PETG/ABS only.

**Not Compatible with TPU,ASA,STTPU,PLA FLEX, Polysmooth PLA/PVB, Nylon and PC filament. PC or PCCF will permanently bond to the surface.

Notes :

- Use only water to clean the build surface. No detergent or solvents are needed. Strictly do not use IPA, Alcohol or Acetone to clean the surface. This will destroy the coating and properties and the plate may be rendered unusable.

- Do not print TPU, ASA, Nylon, PC or PC CF or any PC blend filament on the surface. Nylon and PC will permanently fuse with the build surface rendering it useless for any further prints.

- For prying skirts,brims and other thin parts on the build surface use a plastic build plate scraper only. Using a steel spatula or metal blade may permanently scratch and damage the build plate.

- Keep the build plate clean with a damp cloth to prevent grease build up from touching and handling the plate during part removal.